Slurry pumps are the workhorses of many industries, handling abrasive and corrosive materials with ease. Proper maintenance is crucial to ensure their longevity and optimal performance.

Introduction

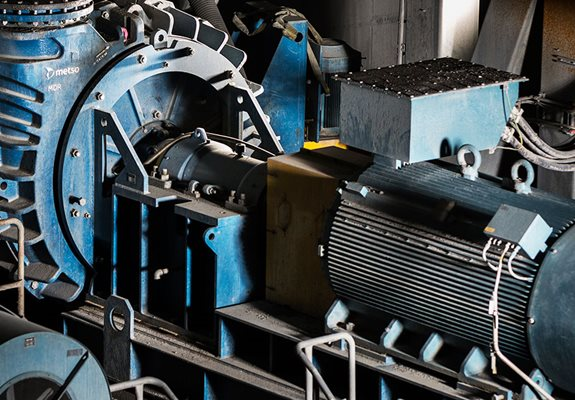

Slurry pumps play a vital role in industries such as mining, dredging, and mineral processing. They are designed to handle mixtures of fluids and solids, known as slurry. Given the harsh operating conditions, these pumps require regular maintenance to prevent downtime and costly repairs.

In this guide, we’ll walk you through the essential steps to maintain your slurry pumps effectively.

1. Regular Inspection

Visual Checks

- Exterior Inspection:

Look for signs of wear, corrosion, or damage on the pump casing and components.

- Leak Detection:

Check for leaks around seals, joints, and connections.

Operational Monitoring

- Noise Levels:

Unusual sounds may indicate internal issues like impeller damage or bearing wear.

- Vibration Analysis:

Excessive vibration can be a sign of misalignment or imbalance.

2. Monitor Wear Parts

Impellers and Liners

- Wear Measurement:

Regularly measure the thickness of impellers and liners. Replace them when they reach the manufacturer’s minimum recommended thickness.

- Material Selection:

Use wear-resistant materials suitable for your specific slurry type.

Seals and Bearings

- Seal Inspection:

Check mechanical seals for signs of leakage or wear.

- Bearing Lubrication:

Ensure bearings are properly lubricated according to the manufacturer’s guidelines.

3. Lubrication

- Lubricant Quality:

Use the recommended grade of lubricant for your pump.

- Lubrication Schedule:

Establish a routine based on operating hours and environmental conditions.

- Automatic Lubrication Systems:

Consider installing for consistent lubricant application.

4. Check Pump Alignment

- Shaft Alignment:

Misaligned shafts can cause premature wear. Use laser alignment tools for precision.

- Coupling Inspection:

Ensure couplings are secure and in good condition.

5. Maintain the Pumping System

Piping and Valves

- Pipe Wear:

Inspect inlet and outlet pipes for erosion or blockage.

- Valve Functionality:

Test valves to ensure they open and close properly.

Strainers and Filters

- Regular Cleaning:

Remove debris that can affect pump performance.

- Replacement:

Replace damaged strainers or filters promptly.

6. Keep Records

- Maintenance Logs:

Document all inspections, repairs, and part replacements.

- Performance Data:

Record operating parameters like flow rate and pressure to identify trends.

7. Training and Safety

- Staff Training:

Ensure personnel are trained in pump operation and maintenance procedures.

- Safety Protocols:

Follow all safety guidelines to prevent accidents during maintenance.

8. Use Genuine Parts

- Manufacturer’s Parts:

Always use genuine replacement parts to maintain pump integrity.

- Warranty Compliance:

Using non-genuine parts may void warranties.

Conclusion

Regular maintenance of your slurry pumps is essential for efficient operation and extended service life. By following these guidelines, you can minimize downtime, reduce repair costs, and ensure your pumps perform at their best.